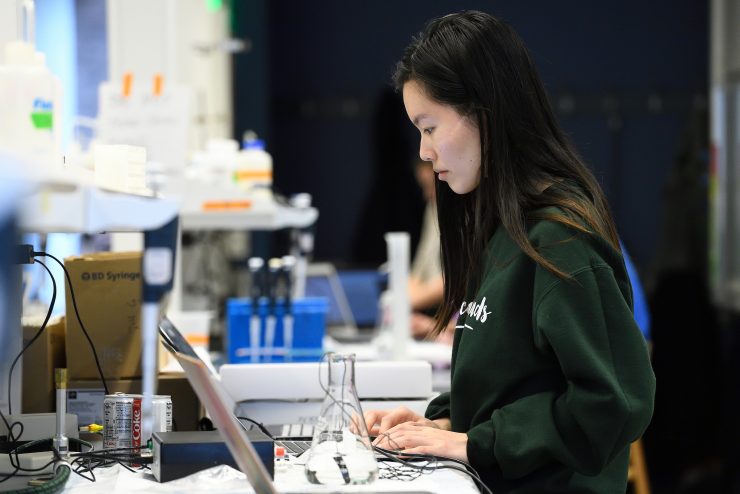

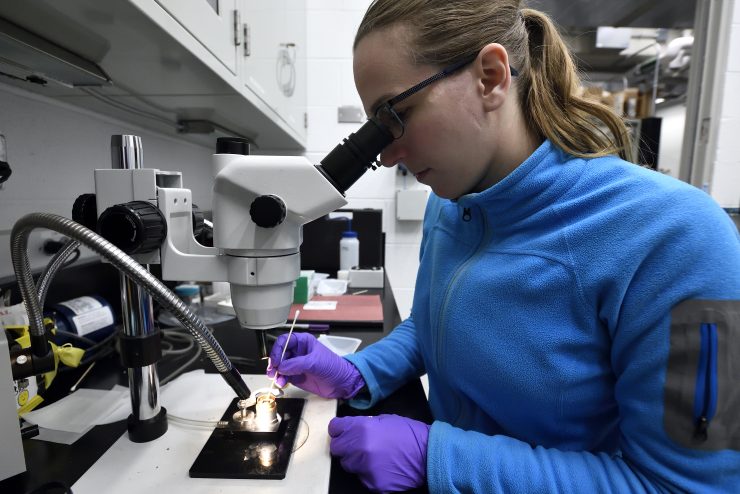

With thousands of research and teaching laboratories on JHU’s Homewood, East Baltimore, and APL campuses, labs represent a significant portion of the university’s physical footprint. However, they also present a unique sustainability challenge: they use 4-5x times more energy and water than a typical office building and generate large quantities of single-use waste annually.

To address this challenge, the Office of Sustainability and Sustainability Leadership Council have founded numerous JHU Green Labs initiatives. Engaging faculty, staff, and student researchers, these Green Lab initiatives aim to support lab users in fostering a culture of sustainability and learning, while minimizing waste and improving resource efficiency.

Stay Informed

Subscribe to the Green Labs listserv to stay up-to-date on all Green Labs initiatives, receive tips on making your lab more sustainable, and share information with other lab users. Subscribers will receive curated emails approximately twice a month.

Implement Best Practices

Learn about green labs best practices and ways to reduce the environmental impact of labs below, ranging from online modules to in-person seminars.

The Office of Sustainability offers 15 – 60 minute trainings on a range of green labs practices including:

- Social and environmental impacts of research (NIH Responsible Conduct in Research topic)

- Role of scientists as responsible members of society (NIH Responsible Conduct in Research topic)

- Skills and professional development relating to green labs best practices

During the 2022-23 academic year, over 10 programs and departments received training from the Office of Sustainability. If you are interested in a green labs training for your program, department, or individual lab, please contact [email protected].

Facilitated by My Green Lab, the Green Lab Ambassador training is a short, online learning tool designed to educate scientists and laboratory professionals on sustainable laboratory practices. Globally, thousands of individuals in academic, government, and private-sector labs have become My Green Lab Ambassadors.

The 70-minute training consists of 4 modules that follow a single lab’s journey towards a sustainable laboratory environment through actionable steps in each of the following topical areas:

- Energy

- Waste

- Water

- Green Chemistry & Community

If you are a JHU affiliate, you can access the training through your myLearning Portal or by searching “Become a Green Lab Ambassador Training Bundle” in the myLearning course catalog. Follow the instructions on the Bundle homepage to complete the training, and ensure you upload the certificate of completion from My Green Lab once received. If you have any difficulties, email [email protected].

For a quick introduction to green labs best practices, review our Green Labs Best Practices Guide which covers topics including:

- Equipment plug loads

- Large equipment (fume hoods, biosafety cabinets, ultra-low temperature freezers)

- Green Chemistry

- Waste Reduction

- Infrastructure

Become a Certified Green Lab

The Green Lab Certification process educates and engages JHU scientists who wish to reduce the environmental impact of their lab. By incorporating personalized best practices identified by the Office of Sustainability, labs can foster a culture of sustainability that can help preserve energy and water, reduce waste, and save money all while remaining safe and supporting the groundbreaking research done at JHU. Email [email protected] to learn more and get started today!

JHU uses the My Green Lab Certification, a regularly updated program that is the gold standard in laboratory sustainability best practices. The program is endorsed by the Association for the Advancement of Sustainability in Higher Education, International Institute for Sustainable Laboratories, and recognized as key measure of progress by the United Nations Race to Zero campaign for the pharma and medtech industries. Across the academic, government, and private sectors, over 1,000 labs have been certified using the My Green Lab Certification.

Certification is free for all JHU-affiliated labs but requires approval from the principal investigator or person in charge of the lab space. At least 50% of a lab’s personnel is required to participate, but for best results, full lab participation is encouraged. The process takes 6-12 months to achieve certification and is an empowering opportunity for JHU’s lab community. Labs are certified as Silver, Gold, Platinum, or Green Level based on performance, their self-assessment, and number of Sustainability Action points earned. Once certified, labs are encouraged to continue improving practices and recertify every two years.

The first two labs at JHU were certified in December 2020. As of February 2023, 17 labs have been certified at JHU and 13 more are at the Commitment level pursuing certification.

The JHU Green Lab Certification covers the 14 topic areas covered by the My Green Lab Certification seen below.

![]()

In addition, advanced certifications levels require labs to earn Sustainability Action Points, ranging from participation in recycling programs to completion of Green Lab Ambassador training.

A lab reaches the Commitment Level after they agree to begin the certification process and are allotted up to 3 months to complete the baseline self-assessment. Following completion of the baseline self-assessment, they will remain at the Commitment Level until they have become certified.

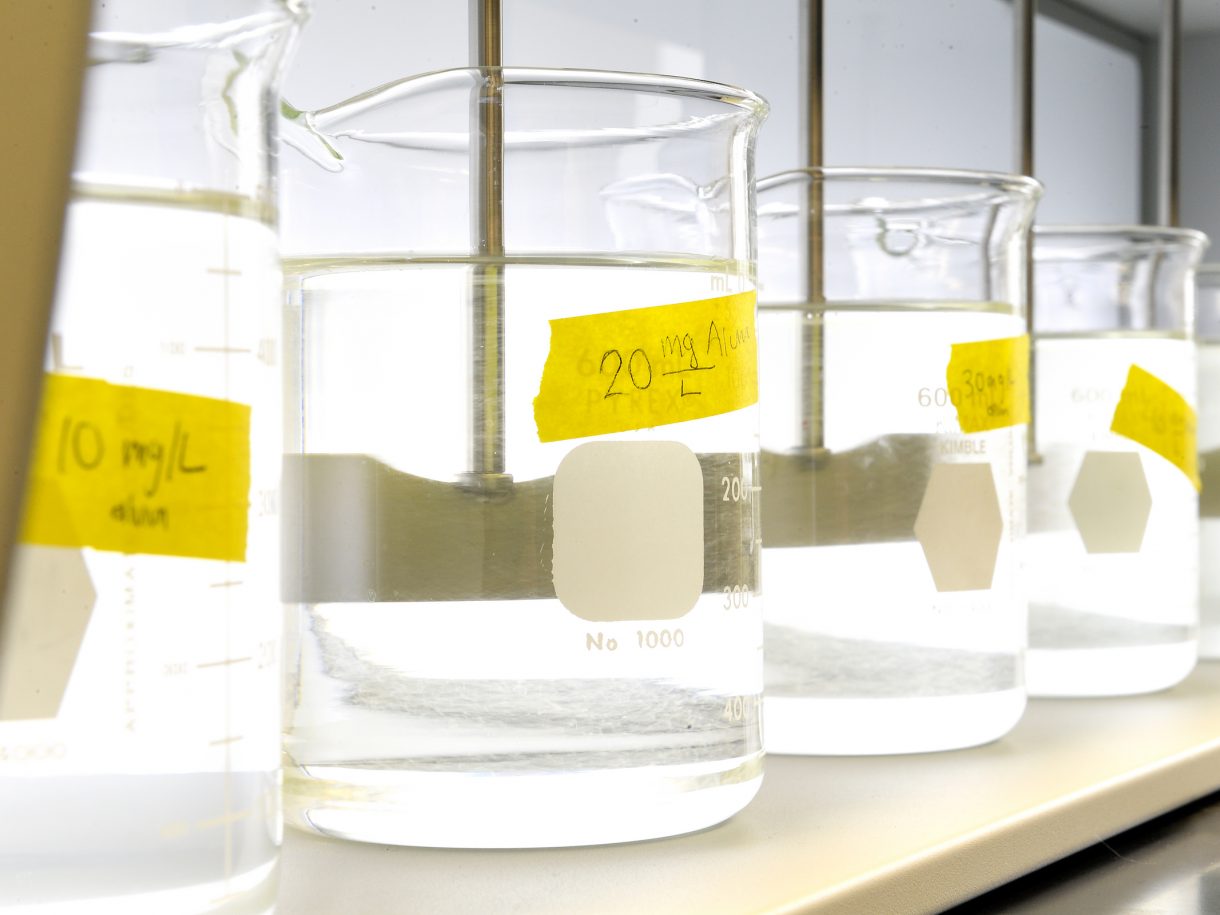

Join the Freezer Challenge

Did you know that ultra-low temperature (ULT) freezers (-70C and below) consume as much electricity as a typical single-family household and that JHU maintains over 1,500 ULT freezers? Lower your lab’s carbon footprint, improve sample safety, and prolong the life of your freezers by improving your cold storage practices.

Did you know that ultra-low temperature (ULT) freezers (-70C and below) consume as much electricity as a typical single-family household and that JHU maintains over 1,500 ULT freezers? Lower your lab’s carbon footprint, improve sample safety, and prolong the life of your freezers by improving your cold storage practices.

Top-performing JHU labs can earn up to $5,000 in awards! Sign up for the Freezer Challenge here.

Supported by the International Institute for Sustainable Laboratories and My Green Lab, the challenge is designed to promote best practices in cold storage management for laboratories around the world. Harnessing the spirit of competition, the Freezer Challenge encourages laboratories to achieve greater energy efficiency, sample integrity, and sample access. In 2022, over 1,200 labs from over 27 countries participated in the Freezer Challenge to save 9.5 million kWh of energy. Labs competing at JHU saved an estimated 767 kWh/day!

The Freezer Challenge focuses on best practices in four key areas, many of which labs may already be doing.

- Inventory management

- Temperature tuning

- Retirements and Upgrades

- Cutting-Edge Practices

In addition to making your lab and JHU more sustainable, the top performing labs from each school/campus below can win up to $5,000 in awards to be used for sustainable purchases, upgrades, or repairs. In previous years, labs have used their awards to make ULT freezer repairs and purchase new efficient freezers and other equipment.

Awards will be given to top performing labs from each below:

- School of Medicine

- Bloomberg School of Public Health

- Homewood Campus (combined Krieger School of Arts and Sciences & Whiting School of Engineering)

In 2022:

- School of Medicine : Elizabeth Jaffee Lab

- School of Public Health: Ana Rule Lab

- Homewood Campus: Jeff Wang Lab

In 2021:

- School of Medicine Lab: Daniela Cihakova Lab

- School of Public Health: Ana Rule Lab

- Homewood Campus: Jeff Wang Lab

Lab Waste & Recycling

JHU’s world-leading research produces hundreds of tons of laboratory waste annually. While much of this waste is required to be disposed as biohazardous waste, certain lab products can be diverted from landfill and incineration through specialty recycling or composting programs.

In addition to recycling and composting, consider other ways to reduce laboratory waste such as:

- Cutting down on purchasing needs

- Consolidating orders to reduce shipping and packaging

- Purchasing from JHU supply stores or core stores

- Switching to lab supplies made from renewable sources

- Polycarbin products are produced from recycled plastics (including from pipette tip boxes recycled at JHU!)

- Eppendorf Bio-based tubes are produced from recycled cooking oil

- Comparing ACT labels to ensure you are buying products with the lowest environmental impact (ACT label integration coming soon to LabViva)

Looking to Buy or Sell Used Lab Equipment?

Consider utilizing GovDeals, an online marketplace for educational and governmental institutions. Contact [email protected] for more information on setting up an account with your lab/department.

Explore the sections below to see what specialty recycling is available on your campus.

When considering specialty lab recycling below, please ensure your lab is adhering to guidelines outlined for hazardous and biohazardous waste as instructed by JHU Health, Safety, and Environment (HSE).

- #1 and #2 plastics

- Rinsed bottles and jugs with labels removed or defaced bottles

- Paper products such as cardboard and computer paper

- Including cardboard coolers and cardboard insulation

- Nitrile gloves

- Approved Kimberly Clark and Halyard, requires approval by emailing [email protected]

- Film plastic

- Rigid, white Styrofoam/expanded polystyrene

- Free of tape, labels, and packing peanuts

- Pipette tip boxes, wafers, cartridges and plastic conical tube racks

- NO PIPETTE TIPS

- Drop off locations on Homewood campus: Mudd Tunnel, Croft basement

- If you would like to request a drop-off location within your building, email [email protected]

- #1 and #2 plastics

- Rinsed bottles and jugs with labels removed or defaced bottles

- Paper products such as cardboard and computer paper

- Including cardboard coolers and cardboard insulation

- #1 and #2 plastics

- Rinsed bottles and jugs with labels removed or defaced bottles

- Paper products such as cardboard and computer paper

- Including cardboard coolers and cardboard insulation

- Pipette tip boxes, wafers, cartridges and plastic conical tube racks

- NO PIPETTE TIPS

- Drop off locations on E. Baltimore campus: MRB dock, CRB II dock, 2024 building, 1812 Ashland, the Genomic Center

- If you would like to request a drop-off location within your building, email [email protected]

Please note the above recycling may not be available in buildings that are primarily associated with Johns Hopkins Hospital.

Please email [email protected] for information on specialty recycling at the other JHU-affiliated campuses.

Green Labs Best Practices

To further reduce your environmental footprint, review our Green Labs Best Practices Guide. Feel free to use the version that best suits your needs!